How Contaminants Are Removed from Compressed Air

Published by Ultramax Systems on 30th Jun 2025

Compressed air may look clean—but it’s often filled with contaminants like dirt, water, and oil that can damage equipment and compromise product quality. Achieving ISO 8573-1:2010 compliant air requires more than just a good compressor. It involves a well-structured multi-stage filtration system.

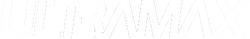

The diagram above illustrates how a properly designed compressed air system removes contaminants such as dirt, oil, water, and vapours in multiple stages to deliver ISO 8573-1:2010 compliant clean air.

1. Air Intake from the Atmosphere

Ambient air enters the system carrying a mix of:

-

Dust and solid particles

-

Micro-organisms

-

Water vapour and liquid

-

Oil aerosols and vapours

-

Potentially harmful gases

These contaminants are invisible to the eye but extremely harmful to pneumatic systems and sensitive tools.

2. Compression Stage

As the air is compressed by the ULTRAMAX Air Compressor, contaminant concentration spikes—up to 800% at 7 bar(g). Compressing air without filtration traps and intensifies all impurities.

3. Air Receiver Tank

The compressed air enters a storage receiver which:

-

Acts as a pressure buffer

-

Allows some condensation of water

-

Reduces pulsation in the air supply

This helps ease the burden on downstream filters and stabilises flow.

4. Primary Filtration (Bulk Removal)

-

WS – Water Separator: Removes bulk liquid water from the system.

-

MX – 1 Micron Particulate Filter: Captures fine solid particles (dust, rust, metal shavings).

At this point, much of the visible contamination is removed.

5. Refrigerated Air Dryer

Next, the air passes through a refrigeration dryer, which:

-

Lowers the air temperature

-

Causes remaining water vapour to condense

-

Removes additional moisture to achieve a dewpoint of ≤ +3°C (Class 4 Water)

This ensures the air is dry enough for most general-purpose industrial applications.

6. Fine Coalescing and Vapour Filtration

-

MY – 0.01 Micron Coalescing Filter: Removes nearly all oil aerosols and ultra-fine particles.

-

MA – Activated Carbon Filter: Eliminates oil vapours and odours, achieving Class 2 Oil standard.

By this point, the air is almost completely clean and free of harmful contaminants.

7. Condensate Management

All separated liquids—oil and water—are directed to an Oil/Water Separator, which safely collects and removes waste fluids while ensuring clean water discharge.

8. Clean Air Delivery

The system delivers clean, dry, and oil-free compressed air, suitable for:

-

General manufacturing

-

Assembly and automation

-

Air tools and pneumatic actuators

-

Instrumentation and sensitive equipment

This final output complies with ISO 8573-1:2010 Class 2.4.2, making it ideal for critical industrial environments.